vertical integration

Our multi-discipline, highly talented team can champion

your products from ideas to market.

Our capabilities: your competitive advantage

Manufacturing sophisticated products involves a wide range of disciplines and high levels of expertise. Our multi-discipline team works as a cohesive unit to deliver seamless vertical integration throughout the product life cycle.

At Memjet D+M, we draw on extensive engineering, science and technology expertise, applying more than 2,000 years of accumulated manufacturing knowledge to your projects.

Full service product development

Extensive investment in process and people

Global supply chains and networks

Capabilities

We harness the talents OF an inter-disciplinary team of experts

Innovative product design and manufacture takes intelligent, skilled and team-oriented people who work cohesively to deliver technically advanced products in competitive time frames. Our in-house capabilities include:

Product, component and equipment design

Chemistry and materials science

Embedded firmware development

Hosted software development

Mechanical, electrical and mechatronics engineering

Micro-Electro-Mechanical Systems (MEMS) design

Systems engineering

Reliability and test engineering

Advanced prototyping, feasibility and failure analysis

Project and program management

Commercialisation and marketing support

Customer and field support

Intellectual Property and Patents

Memjet D+M’s culture is steeped in the capture and protection of intellectual property. Over the past seven years, Memjet has generated 183 US patents held in diverse technology fields such as MEMS, mechanical engineering, mechatronics, chemistry, materials science, fluidic systems and image processing. We have partnered with global industry giants, including HP and Canon, to cross-license innovations and fuel further product development. Proudly, we can share that:

- Our inventions have all been designed and developed in Australia.

- Our patent applications are drafted in-house using an experienced patent team with expertise in the US and European jurisdictions.

- With in-house patent expertise at our disposal, we achieve market leading efficiencies in both time-to-market and cost.

Chemistry and Materials science

At Memjet D+M, our first-class materials testing unit has extensive chemistry expertise. The team is rich in knowledge and experience with a high proportion of members having PHDs and over ten years laboratory experience. Our goal is to use science to advance our product to the forefront of design.

The team specialises in the development and qualification of custom materials to determine manufacturability, yield and cost. We also support our partners by facilitating reverse engineering, failure analysis and contaminant identification. We are proud to offer our partners:

- Cost efficiencies created with advanced in-house chemical testing such as dynamic mechanical analysis (DMA), thermogravimetric analysis (TGA) and scanning electron microscopy.

- Advanced chemical detection capabilities with applications in defence and medtech products.

- Dynamic Light Scattering (DLS) to analyse small particles in polymers and suspensions and coulter counter capabilities to detect particle size and quantity.

- Access to our high-volume lab that uses Clinical Mass Spectrometry and High Performance Liquid Chromatography (HPLC).

Mechanical Engineering

Our mechanical engineering team focuses on future-oriented product designs that are feasible, real-world-tested and scalable. We aim to push the boundaries of science, technology and industrial engineering to develop future-ready products that are cost effective to produce. Capabilities in our mechanical engineering division include:

- Precision injection molding, part and assembly design and robotic manufacturing design.

- Microfluidic design and development, including elastomeric seals and couplings.

- Precision micro-positioning system design.

- Medical product design including implantable devices and respiratory assistance systems.

- Automotive sensor design and testing.

- Electro-mechanical assembly design and testing.

- Industrial engineering and design for manufacture.

- Computer aided design, product simulation and prototype development.

Software Capabilities

High-calibre software development capabilities are an essential part of modern manufacturing. Our automated, smart manufacturing processes are driven by sophisticated software programs that are customised to each project. Our in-house software team delivers fast development times for our partners, with expertise in each of the following areas:

- Software architecture from concept to high-level specifications and detailed designs.

- Software development from low level interrupts and hardware drivers through to middleware and host-based software.

- Secure software for manufacturing communication protocols plus implementation and review.

- Multi-threaded and multi-processor software designs plus embedded real-time operating systems.

- The development of proof of concept software to test innovation feasibility and real world application.

- Graphical user interface (GUI) design to support the development of intuitive and easy-to-use products.

- The development of security software for IoT devices (devices connecting to the internet) plus security systems to protect commercial activity against theft and counterfeiting.

- In-house development of machine vision software that enables flexible camera control, image analysis and interpretation.

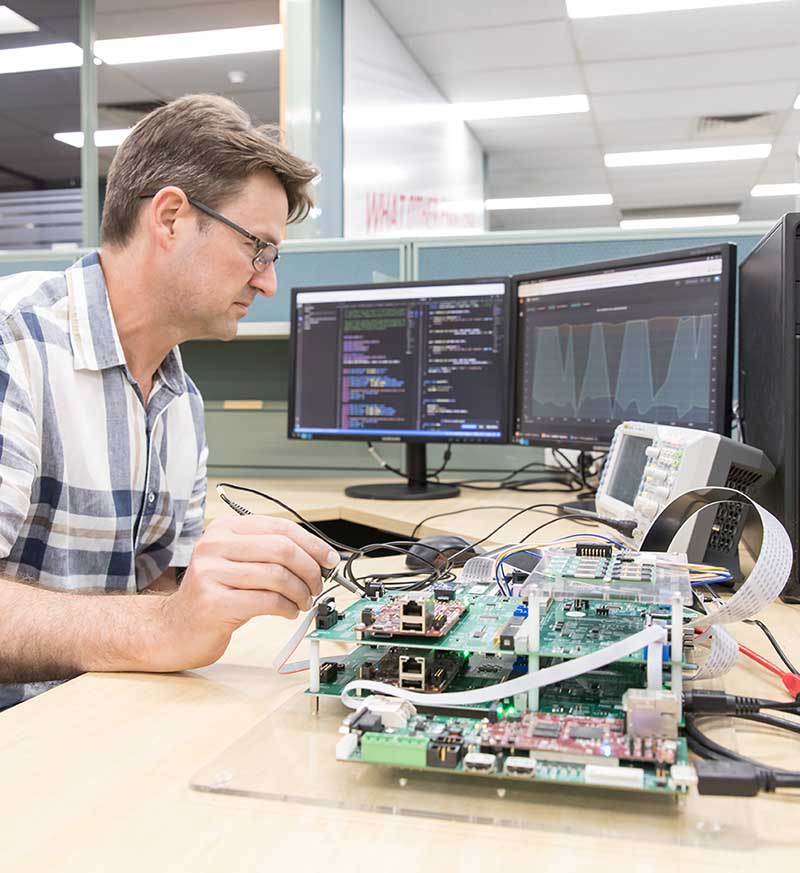

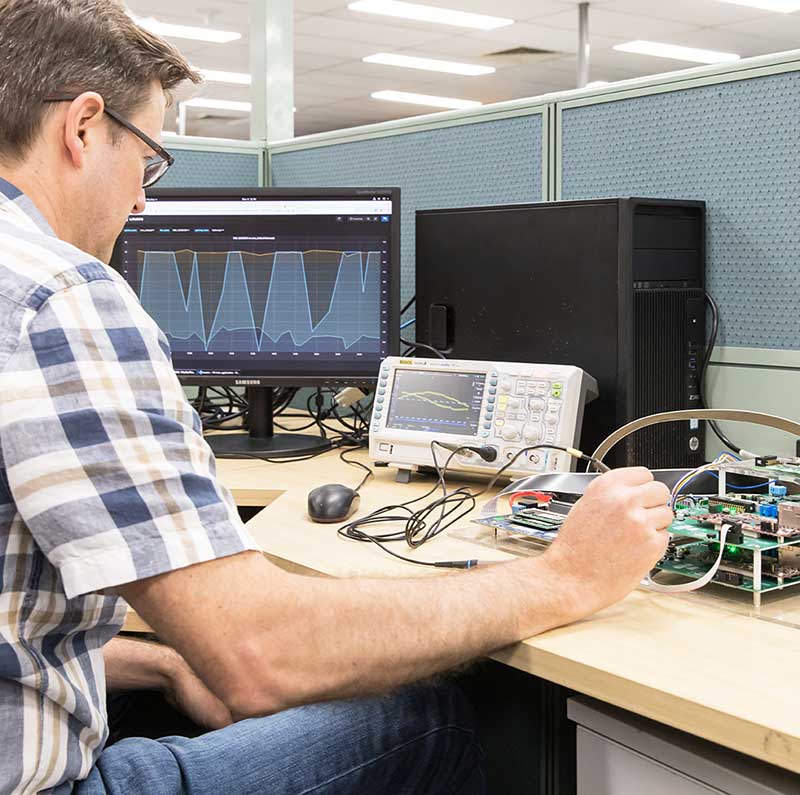

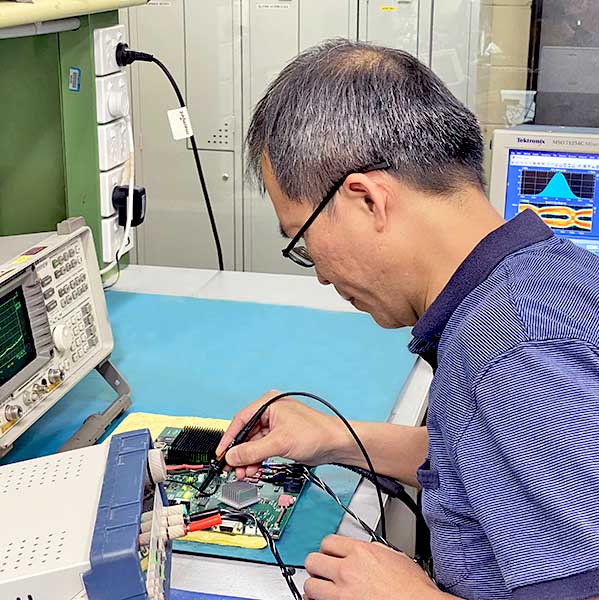

Microelectronics

Microelectronics are a key enabling technology behind technological advancement and product innovation. Memjet D+M provides access to high-performance printed circuit board assemblies (PCBAs) customised for use in a wide range of electronic applications. Our partners enjoy access to:

- PCBA design expertise focusing on high speed analogue systems, microcontrollers and SoC chips.

- Access to high power, low voltage switching supplies, electromechanical controls, sensor interfaces, Field Programmable Gate Array (FPGA) semiconductors and embedded software.

- Prototype design facilitated by our relationships with fast turn, flexible suppliers.

- Prototype bench testing, verification, qualification and regulatory compliance testing, including electromagnetic compatibility testing (EMC).

- Established relationships with high volume manufacturing partners and suppliers.

Precision Tool Making

Memjet D+M’s in-house precision tool design and manufacturing service supports lean manufacturing and decreases time-to-market. Our engineers can produce precision tools to suit each stage of the product life cycle. This in-house approach supports value creation due to fast modifications and minimised disruption to the production process. Some of our tool making capabilities include:

- An experienced team of precision tool makers and Computerised Numerical Control (CNC) machining specialists.

- CNC machining centres with axis mills, CNC lathes and high-speed micro-mills.

- CNC wire cutting and surface grinding machines.

- Manual milling, turning and prototype part manufacture plus prototyping and machine fitting and commissioning.

- CO² laser cutting and 3D printing machines for prototyping and jig manufacture, including soft and hard polymers.

- Tig welding, mold machining and casting elastomers and resins plus sheet metal cutting, folding bead blasting, rumbling and pressure cleaning.

What can Memjet D+M do for you?

Are you looking for a value-add partner to provide full support throughout the innovation journey? We can help.

Memjet is the global leader in providing digital inkjet technology that enables beautiful precision, simplicity and affordability.

Leveraging this advanced manufacturing capability for its partners, Memjet D+M is shaping the future of innovation with ingenuity, precision and value.